Sheet Metal Laser Cutting Machine

Product Details:

- Product Type Cutting Machine

- Material Metal

- CNC Or Not CNC

- Computerized Yes

- Automatic Grade Automatic

- Cooling Mode Water Cooling

- Weight (kg) 4000 Kilograms (kg)

- Click to view more

Sheet Metal Laser Cutting Machine Price And Quantity

- 3000000 INR/Unit

- 2 Unit

Sheet Metal Laser Cutting Machine Product Specifications

- Metal

- CNC

- Cutting Machine

- High Efficiency

- Water Cooling

- 4000 Kilograms (kg)

- Automatic

- Yes

- 4560 x 2880 x 1800 Millimeter (mm)

Sheet Metal Laser Cutting Machine Trade Information

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 10 Unit Per Month

- 15 Days

- Jammu and Kashmir, Tripura, Manipur, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Nagaland, South India, East India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, West Bengal, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Haryana, Gujarat, Delhi, North India, Andhra Pradesh, Kerala, Central India, Odisha, West India, Chhattisgarh, All India

Product Description

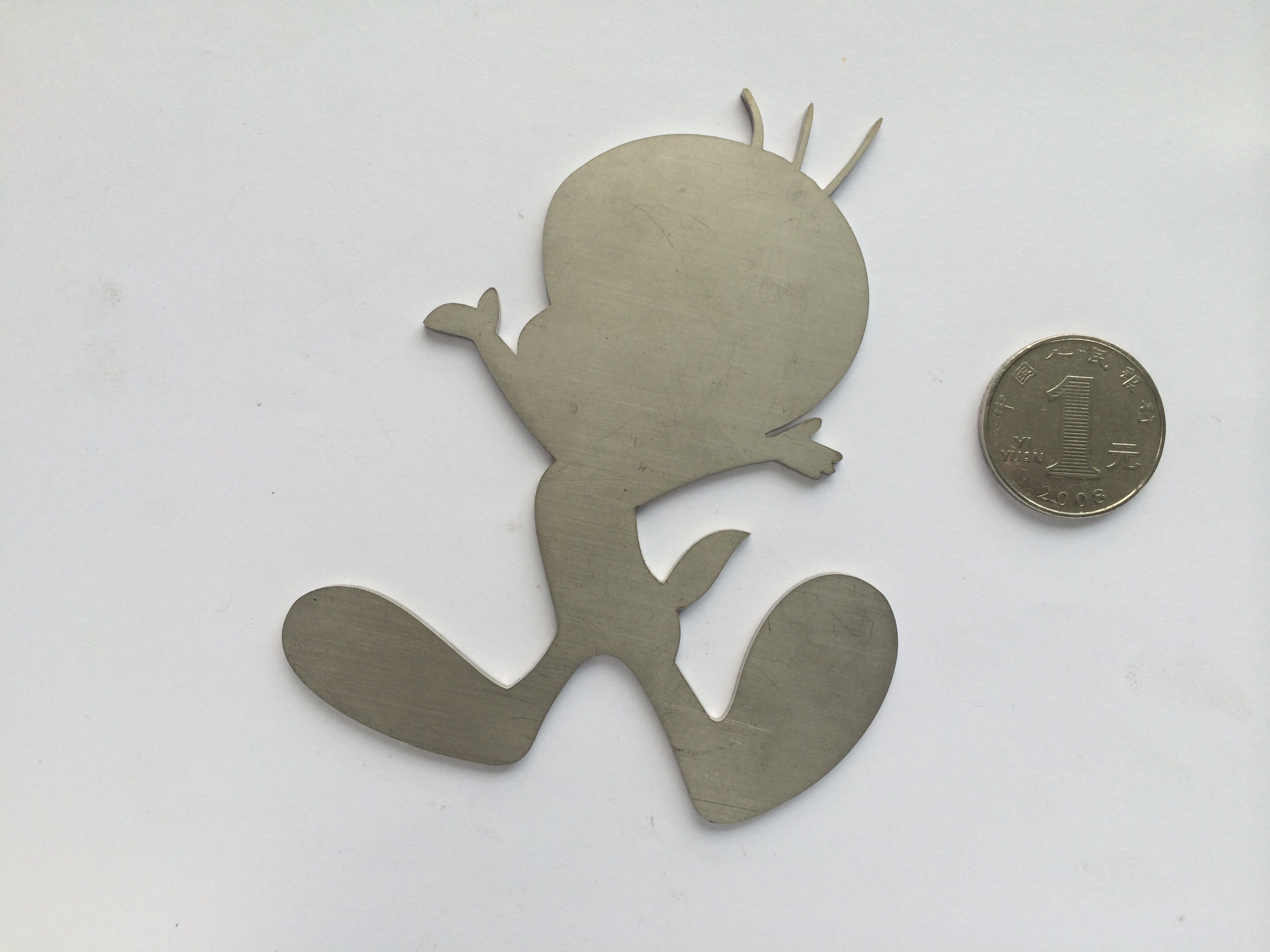

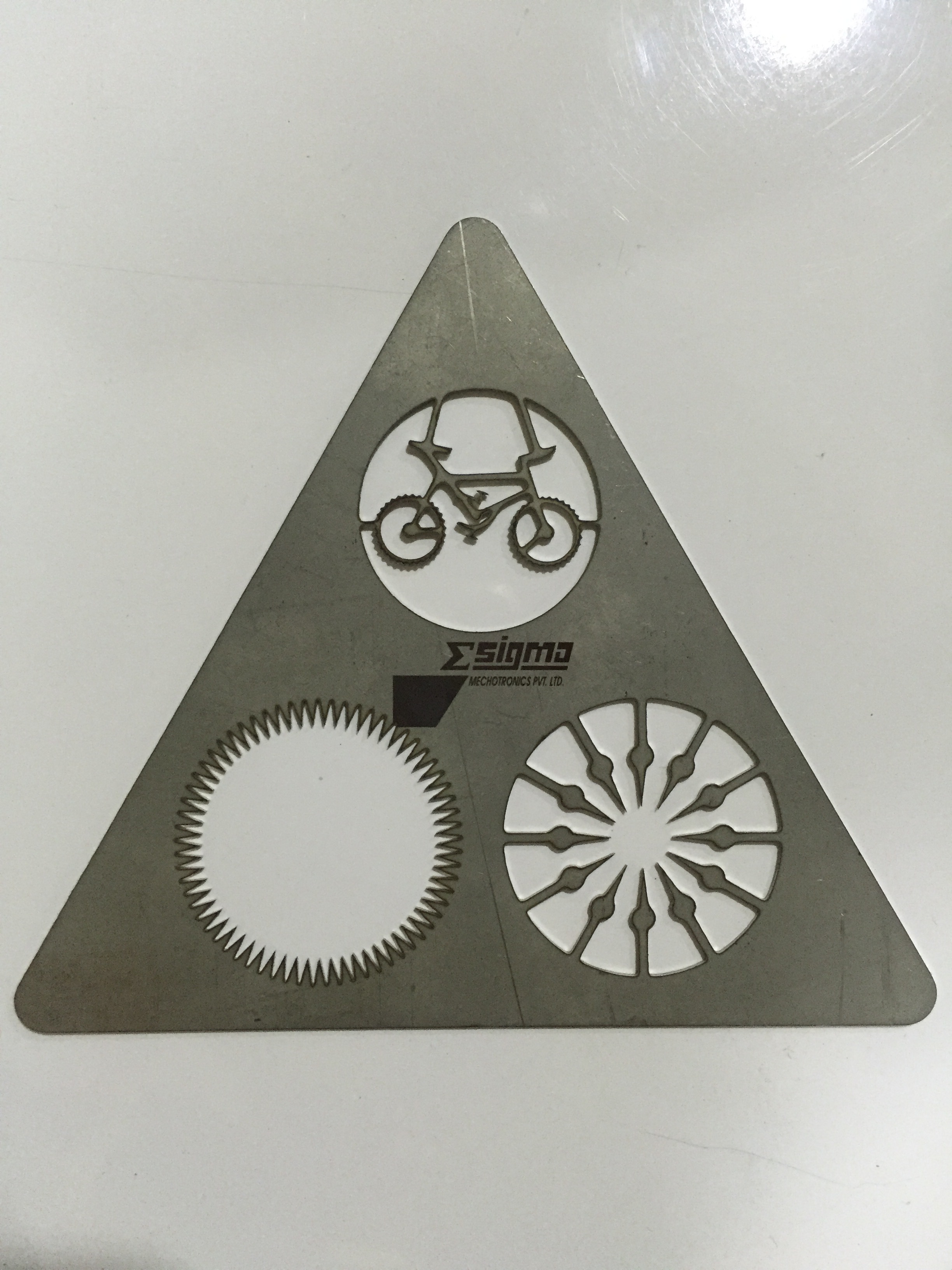

Sheet Metal Laser Cutting Machine is designed in different laser options from 1KW, 2KW, 3KW, 4KW to 8KW. This unique machine comes with low energy consumption features along with swift cutting ability and minimum maintenance cost. This comes with high productivity features that ensure constant working of machine for 100,000 hours. Durable dust collection covers are provided that are opened and closed as per the position of the cutting head. In addition to this, the shuttle table system is ideal for enhancing the workflow.

| Max. laser Power | 1000W* |

| Wave length | 1064nm |

| Working size | 1500 x 3000* |

| Max. positioning speed | 100m/min |

| Max. accelerated | 1.5G |

| X/Y axis positioning accuracy | + 0.05mm |

| X/Y axis re-positioning accuracy | + 0.03mm |

| Working voltage | 380V 50Hz |

| Total Power | 20KW* |

| Max. weight can bear | 4000kg* |

| Device Dimensions | 8200x3000x2000 mm* |

| Transmission | Precise pinion and rack, dual-drive transmitting |

Efficient CNC Sheet Metal Cutting

The machines advanced CNC system ensures precise cutting for complex sheet metal designs, significantly reducing manual intervention and production time. Its computerized controls enable consistent quality and repeatability, making it suitable for high-volume manufacturing environments.

Superior Cooling Performance

With a dedicated water cooling mode, the machine maintains optimal operating temperatures during prolonged cutting activities. This feature supports increased machine lifespan and minimizes downtime, especially in rigorous industrial usage.

FAQs of Sheet Metal Laser Cutting Machine:

Q: How does the water cooling system benefit the laser cutting machine during operation?

A: The integrated water cooling system efficiently dissipates heat generated during cutting, maintaining stable temperatures. This ensures longer machine life, consistent cutting performance, and reduces the risk of overheating during intensive use.Q: What metals can be processed using this laser cutting machine?

A: The machine is designed for cutting various types of metal sheets, including stainless steel, carbon steel, aluminum, and other compatible alloys. The high efficiency and powerful laser accommodate diverse industrial material requirements.Q: Where can I purchase or source this sheet metal laser cutting machine in India?

A: You can acquire the machine through a network of Indian distributors, suppliers, manufacturers, importers, and traders. The extensive availability ensures prompt service and support nationwide.Q: What is the process for setting up and operating the CNC sheet metal laser cutting machine?

A: Setup involves placing the machine according to its specified dimensions, connecting water cooling lines, and calibrating the CNC controls. Once programmed, automated operation allows users to efficiently load designs and achieve precise cuts.Q: Who benefits most from using this automatic, CNC-equipped laser cutting machine?

A: Industrial users such as metalworking factories, automotive manufacturers, and fabrication units benefit greatly. The automatic grade and computerized features enhance production speed and accuracy, elevating operational efficiency.Q: When should regular maintenance be performed on this machine?

A: Routine maintenance should be conducted according to the manufacturers guidelines, typically after a set number of operating hours or monthly. This includes checking water levels, cleaning optics, and inspecting mechanical components to ensure optimal performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+