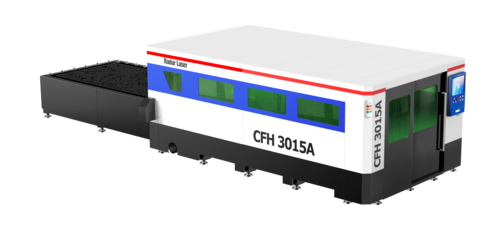

Fiber Laser Cutting Machines

Price 3500000 INR/ Unit

Fiber Laser Cutting Machines Specification

- Product Type

- Cutting Machine

- Laser Type

- Fiber Laser

- Material

- Metal

- Computerized

- Yes

- Automatic Grade

- Automatic

- Cooling Mode

- Water Cooling

- Weight (kg)

- 250-280 Kilograms (kg)

- Feature

- High Performance, High Efficiency

Fiber Laser Cutting Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 15 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Fiber Laser Cutting Machines

Fiber Laser Cutting Machine

We are manufacture of Fiber Laser Cutting Machine. Also we are manufacturer of Laser Cutting Products & CNC Automation Solutions.

| Max. laser Power | 1000W* |

| Wave length | 1064nm |

| Working size | 1500 x 3000* |

| Max. positioning speed | 100m/min |

| Max. accelerated | 1.5G |

| X/Y axis positioning accuracy | + 0.05mm |

| X/Y axis re-positioning accuracy | + 0.03mm |

| Working voltage | 380V 50Hz |

| Total Power | 20KW* |

| Max. weight can bear | 4000kg* |

| Device Dimensions | 8200x3000x2000 mm* |

| Transmission | Precise pinion and rack, dual-drive transmitting |

*Options Available

Advanced Fiber Laser Technology

Harness the power of automated fiber laser technology for fast and precise metal cutting in manufacturing and fabrication industries. Our machines offer superior performance and minimal maintenance, thanks to features like water cooling and fully computerized operation.

Efficient and Reliable Operation

Designed with high efficiency and built for durability, these laser cutting machines streamline processing, reduce downtime, and ensure consistent output. The automatic grade enhances user experience, making production easier and smoother even for complex designs.

FAQ's of Fiber Laser Cutting Machines:

Q: How does the water cooling system benefit fiber laser cutting machines?

A: The water cooling system helps regulate the temperature of the fiber laser and machine components, ensuring stable performance during prolonged operation and preventing overheating, which extends the machine's lifespan.Q: What materials can these fiber laser cutting machines process?

A: These machines are engineered specifically for cutting metal materials, including stainless steel, carbon steel, and aluminum, enabling high precision for various industrial applications.Q: When should manufacturers choose automatic grade fiber laser cutting machines?

A: Manufacturers should opt for automatic grade machines when they need streamlined production, higher efficiency, and precise control for complex and repetitive cutting processes.Q: Where can these fiber laser cutting machines be installed?

A: They are suitable for installation in fabrication shops, metalworking plants, manufacturing units, and industrial facilities throughout India, supported by distributors, traders, and suppliers.Q: What is the process of operating a computerized fiber laser cutting machine?

A: Operators create or upload cutting designs onto the machine's computerized system, which automates the cutting path and executes precise metal cuts with minimal manual intervention.Q: What are the benefits of using high performance fiber laser cutting machines?

A: Users gain advantages such as increased productivity, superior accuracy, reduced labor requirements, and lower operational costs, making these machines ideal for competitive industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laser Cutting Machine Category

Industrial Cnc Laser Cutting Machine

Price 4500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Metal

Product Type : Cutting Machine

Automatic Grade : Automatic

CNC Or Not : CNC

Sheet Metal Laser Cutting Machine

Price 3000000 INR / Unit

Minimum Order Quantity : 2 Units

Material : Metal

Product Type : Cutting Machine

Automatic Grade : Automatic

CNC Or Not : CNC

Fiber Optic Laser Cutting Machine

Price 3500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Metal

Product Type : Cutting Machine

Automatic Grade : Automatic

CNC Or Not : CNC

Send Inquiry

Send Inquiry