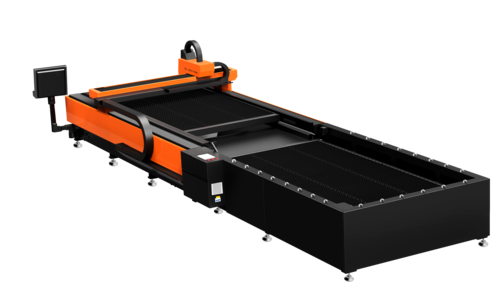

Precision Metal Laser Cutting Machine

Price 4500000 INR/ Unit

Precision Metal Laser Cutting Machine Specification

- Product Type

- Cutting Machine

- Laser Type

- Fiber Laser

- Material

- Metal

- CNC Or Not

- CNC

- Automatic Grade

- Automatic

- Voltage

- 380 Volt (v)

- Feature

- High Performance

Precision Metal Laser Cutting Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 15 Days

- Main Domestic Market

- Jammu and Kashmir, Manipur, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, South India, East India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Goa, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Nagaland, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Haryana, Gujarat, North India, Andhra Pradesh, Kerala, Central India, Odisha, West India, Chhattisgarh, All India

About Precision Metal Laser Cutting Machine

| Max. laser Power | 1000W* |

| Wave length | 1064nm |

| Working size | 1500 x 3000* |

| Max. positioning speed | 100m/min |

| Max. accelerated | 1.5G |

| X/Y axis positioning accuracy | + 0.05mm |

| X/Y axis re-positioning accuracy | + 0.03mm |

| Working voltage | 380V 50Hz |

| Total Power | 20KW* |

| Max. weight can bear | 4000kg* |

| Device Dimensions | 8200x3000x2000 mm* |

| Transmission | Precise pinion and rack, dual-drive transmitting |

Advanced Cutting Technology for Industrial Use

Our laser cutting machine employs state-of-the-art fiber laser technology, delivering optimal performance and reliability for industrial metal cutting. The machine's automatic CNC capabilities enable effortless, repeatable, and precise operations, making it suitable for a wide range of applications including fabrication, automotive parts, and custom metalworks.

Automatic and Efficient Operation

With its fully automatic grade, the device ensures streamlined workflow and consistent output. Operators can easily program cutting parameters through the CNC interface, significantly reducing manual labor and human error, thus enhancing productivity and finished product quality.

FAQ's of Precision Metal Laser Cutting Machine:

Q: How does the Precision Metal Laser Cutting Machine operate?

A: This machine uses fiber laser technology, controlled by CNC automation, to cut through metal sheets with high precision. Operators input desired designs or measurements, and the automatic system executes the process efficiently.Q: What materials can be processed with this laser cutting machine?

A: The machine is specifically designed for cutting various types of metal, making it a versatile solution for industries such as automotive, fabrication, and construction.Q: When is using a fiber laser cutting machine most beneficial?

A: It is particularly advantageous when high precision, complex shapes, and clean edges are required in metal components, or when consistent repeatability is essential in mass production.Q: Where is this machine typically used?

A: The laser cutting machine is widely adopted in manufacturing units, fabrication workshops, sheet metal processing plants, and other facilities engaged in industrial-scale metalworking projects across India.Q: What is the process for operating this automatic CNC machine?

A: Users program the required cutting patterns into the CNC system, load the metal sheet, and initiate the fiber laser. The machine then performs cutting operations automatically, ensuring accuracy and uniformity.Q: What are the main benefits of choosing a high-performance CNC fiber laser cutter?

A: Major benefits include unmatched cutting accuracy, reduced production time, low operational costs, minimization of material waste, and improved safety due to automation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laser Cutting Machine Category

Fiber Laser Cutting Machine For Plate

Price 4500000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Automatic Grade : Automatic

Material : Metal

Laser Type : Fiber Laser

Metal Fiber Laser Cutting Machine

Price 3000000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Automatic Grade : Automatic

Material : Metal

Laser Type : Fiber Laser

MS Fiber Laser Cutting Machine

Price 4500000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Computerized : Yes

Automatic Grade : Automatic

Material : Metal

Laser Type : Fiber Laser

2000W Fiber Laser Cutting Machine

Price 4000000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Automatic Grade : Automatic

Material : Metal

Laser Type : Fiber Laser

Send Inquiry

Send Inquiry